Deutscher Drucker 09/23 Recipe for success: Creativity plus scratch resistance

Recipe for success: creativity plus scratch resistance

The fact that Achilles from Celle was named “Creative Printer of the Year 2022” may have initially surprised some in the industry, as the name has been synonymous with laminating services in particular for decades. The Druck&Medien Award now testifies to the strong change that the company has made in recent years. Today Achilles stands on many pillars. By Gerd Bergmann

One of these mainstays is Achilles Presentation Products GmbH, which offers unusual packaging with a variety of surfaces and features.

More class instead of quantity

Fabian Roessing joined the company in 2017, which his grandfather Werner Achilles founded in 1946, and now runs it as the sole managing partner. Roessing has adapted the Achilles Group to the changing requirements of the market, which can be well described as “less mass, more class”. The demand for finishing printed sheets for the classic commercial market has declined significantly over the past 15 years, which is why the entire company has had to downsize but become much more flexible. Today, 150 of the approximately 300 employees work in Celle, 75 in Budweis, Czech Republic, and the rest at another seven locations in Germany and neighboring countries. They generate around 40 million euros in sales. In Celle, all activities were brought together at one location in the Altencelle industrial area in 2021, despite the corona pandemic. In fact, until 2005, Achilles specialized solely in laminating – and of course in folder and folder production, which is based on this know-how. In the 2000s, the demand for lacquer as a further type of finishing increased, which is why Achilles also offered this service and invested heavily in screen printing technology. Fabian Roessing: “Our DNA and our core business is still the finishing of printed sheets and the production of lever folders and ring binders. However, since these markets are under great pressure, we are increasingly diversifying our position. We have gradually expanded our portfolio in order to be a powerful partner for the packaging industry.”

More for the packaging market

In concrete terms, this means that complete packaging projects such as slipcases or magnetic boxes are offered. Partly as pure contract production, but also partly based on our own designs. Creativity is expected from both packaging and book customers: Achilles can use a variety of surfaces in new or at least unusual combinations. And even without a designated “innovation department,” the Achilles team is extremely resourceful and innovative. For example, a functional and attractive gift packaging for bottles called “B-Joy” was created, which was submitted for the Druck&Medien Award, among others. In this specific case, it was provided with scented varnish (spring meadow) with a lavender flower motif, as well as a textured varnish with a “sand” surface. When it comes to presentation products, Achilles is essentially a full-fledged manufacturer that carries out all the services itself, with the exception of printing. Surfaces are sometimes flocked, NFC chips are integrated or the box for a fine chocolate manufacturer is given a small cooling module so that the precious contents do not melt.

Consulting skills required

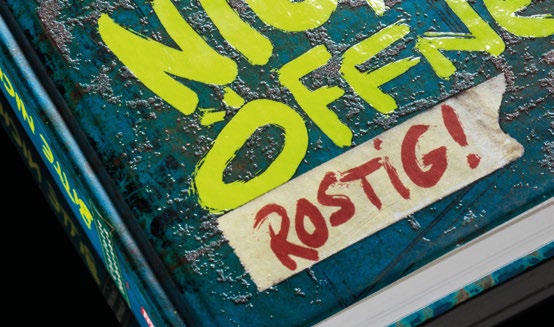

But that also means that advice and sales for this Achilles business area have to be carried out completely differently than, for example, in the laminating and painting services business. Fabian Roessing: “We are the project managers here. This was partly new territory for us.” When it comes to book covers, creative packaging, presentation folders or boxes, the Celle-based company now speaks directly with publishers and branded manufacturers or their agencies. You can score well with consulting skills and surface know-how. On the one hand, when it comes to high-quality packaging, the price may not be down to the last cent, but on the other hand, there are projects in which a lot of time and energy is invested, but which may not be realized at all. But when they are implemented, they are real eye-catchers. For example, the book covers that Achilles created for a children’s book series from Carlsen Verlag. Here, for example, a book was created that, thanks to a scratch-resistant lamination and a convincing “rusty” surface, can withstand more robust use without losing its value. With the use of the scratch-resistant matt film “X-treme matt”, extremely good paint adhesion is possible, which even allowed the tactile varnish (structured glitter varnish) to be stamped onto the book cover in high quality.

Successful product special laminating film

The films from the X-treme series are a successful product anyway. For example, under the name “X-treme Matt Low Migration”, Achilles sells a laminating film worldwide through partner companies that, in addition to its matt appearance and velvety feel, is particularly scratch-resistant and even suitable for indirect food contact. There is now also a scratch-resistant soft-touch version. The unique properties are created by post-coating standard films, which was first implemented by Achilles in 2008 and has been continuously developed since then. The special laminating films now form the company’s strong third pillar

t that Achilles laminating films, together with the laminating adhesive used by Achilles, can be separated very well from the paper surface with a high fiber yield. The result: The paper fibers are then very easy to recycle. It is therefore not surprising that products laminated with Achilles OPP films and with the laminating adhesives used by Achilles are allowed to bear the “Blue Angel” environmental label.

Renewable energy

The overall picture is rounded off by the Achilles Group’s investments in renewable energies. “We have already installed a small photovoltaic system in 2022 and will be installing another system in 2024 put into operation so that we can generate almost 50% of our annual production electricity requirements at the Celle site from renewable energies. Next, a PV system will be installed at the Leipzig location. This is a huge step for us as a family business in these challenging times,” says Fabian Roessing, managing partner of the Achilles Group. “In addition, we will be gradually renewing our car fleet with hybrid and electric cars over the next few years, and since last year we have been offering our employees the opportunity to lease e-bikes through the company via Jobrad,” says Fabian Roessing continues. It is therefore clear that the Achilles Group relies on two strategies when it comes to sustainability. The Achilles Group’s product portfolio is supplemented by sustainable solutions and alternatives that conserve materials and resources. In addition, the family company is increasingly investing in renewable energies. “We will continue to use and process films as a service provider for the printing and packaging industry in the future. Our job is to highlight the ecological options and alternatives available on the market, to further develop them with our partners and to offer them to our customers.

Our aim is for our customers to be successful at the point of sale. We are also making our contribution to this in a society that is increasingly focusing on sustainability and resource conservation,” concludes Fabian Roessing.